The intention of central processing is definitely the orderly processing of clinical and surgical devices to safeguard clients from infections though minimizing risks to staff and preserving the worth on the products staying reprocessed957. Health care facilities really should endorse the identical amount of performance and basic safety while in the preparation of materials in other locations (e.g., working space, respiratory therapy) as is practiced in central processing.

Thriving sterilization techniques are essential for Functioning inside a lab and negligence of this may lead to extreme effects, it could unexpectedly Value a daily life.

Progressive biomanufacturing processes need Superior applications to reliably disconnect factors. The Biosealer® Full Containment (TC) is an automatic warmth sealer for disconnecting thermoplastic tubing within an aseptic Procedure preserving sterile fluid paths.

In central processing, double wrapping can be done sequentially or nonsequentially (i.e., simultaneous wrapping). Wrapping should be performed in this type of manner in order to avoid tenting and gapping. The sequential wrap employs two sheets of your conventional sterilization wrap, a person wrapped following the other. This treatment results in a bundle inside of a package. The nonsequential process takes advantage of two sheets wrapped concurrently so which the wrapping has to be executed just once.

In autoclave temperature boosts as pressure boosts. The relationship among temperature and pressure is as underneath.

Despite size, autoclaves are self-sealing steel vessels that may be discovered in a variety of industries to complete sterilization or other scientific processes greatest carried out in higher-stress and significant-temperature environments.

Use PPE, and mask for the duration of dealing with these equipment. Discard all disposals and carry out hand hygiene just after Each and every dealing with.

An alternate form of filter is a sintered glass filter. These are typically product of glass and, as a result, never take in liquids in the course of filtration. The drawback is read more that they are pretty brittle and split quickly.

SUS include products or assemblies Employed in the production of a drug material or drug item that happen to be discarded as squander soon after one or a number of uses these consist of: disposable chromatography columns, bioreactor, storage baggage for bulk Answer, single-use assemblies, disposable centrifuges, filter cartridges, storage containers for buffers or intermediates, and filter capsules.

Adhesive-backed paper tape with heat-delicate chemical indicator marking that variations colour or Exhibit-diagonal stripes, the text “sterile” or “autoclaved” when exposed to efficient sterilization temperature (121°C) are used to check the efficacy of autoclaves.

The Biosealer® method of sterilization TC provides a extensive 20 mm seal For additional robust disconnection. Furthermore, a chopping guideline embedded into your seal makes certain operators may make a thoroughly clean cut with scissors.

Tubings on the ventilator are contaminated While using the secretion of the patient. The condensate from your inspiratory lines may well spill on the tracheobronchial tree of the client or in to the nebulizer although dealing with, modifying, or manipulating the ventilator circuit.

I want to sign up for newsletters from Sartorius (Sartorius AG and its affiliated organizations) based mostly of my personalized passions.

The most crucial drawback of UV radiation for a sterilizing agent is its poor penetrating electric power. This is the result of powerful absorption by lots of substances. The application of UV radiation is limited.

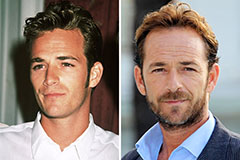

Luke Perry Then & Now!

Luke Perry Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Michael Oliver Then & Now!

Michael Oliver Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now!